Got this email from Autodesk that Fusion is increasing their annual price by a huge amount. I subbed for 1 year a couple years ago for I think $380. Then I was able to get an educational sub after that. Fusion is still the cheapest CAD software out there, not including the free stuff like FreeCAD, but still, this price increase is massive.

It should be noted that it’s still free to use for personal use minus the extra features.

No, no - they’re not raising the price; they’re rebalancing it to reflect the value it delivers!!1!

And since they’ve reduced the free version functionality significantly, I believe I’m due a substantial rebate.

A five finger rebate

I dont use it, but did they bundle any other software in or add any features that would justify the use of the word “rebalancing” or is it just plain old fashioned corporate bullshit?

What did they take out of the free version?

It’s been a little while, but they gutted the mesh editing tools in he free version. They also dropped the number of active models, restricted certain file-functions (maybe assemblies…I don’t do any/many), and limited file import/export.

The problem is that there is no real competitor to fusion. If you think about usability/learning curve

Onshape has replaced fusion for me, was an easy switch.

I find Onshape to be much better than fusion.

Isn’t onshape for non-commercial only?

Non-commercial is the free version, with all your parts public.

They also have a pro license with a fee, where your parts are then private obviously.

The pro license is like $2000 per year.

So TheDuckPrince was right all along.

Ya TheDuckPrince clearly didnt look very hard for competitors, onshape is great.

If on shape had built in CAM like fusion does, I’d switch in a heartbeat.

SolidWorks for Makers seems like a decent competitor. $48/year USD for now.

I thought they got rid of that tier. Might have to try it out if it’s still available.

Seems to still be offered, the license allows up to $2000 profit as well instead of $1000 revenue with fusion.

Nice, someone commented veteran pricing that’s $20 a year, which I qualify for, so definitely going to try it out. Thanks!

That’s a more reasonable threshold, and allows some wiggle room if you have an idea that blows up and makes you a few bucks (what is profit? Can you count your PC and printer as capital expenditures? etc etc).

Autodesk is gonna Autodesk, but they should, at a minimum, match that term.

Yeah, I’ve used multiple CAD tools, from pro/engineer to F360, but the learning curve of freecad felt like a brick wall.

FreeCAD definitely has a steeper learning curve and a few rough edges, but to me it was absolutely worth it to learn. I really don’t like my files subject to the whims of Autodesk.

Yeah, I’ve done some editing in FreeCAD, but I’m lost at the rest.

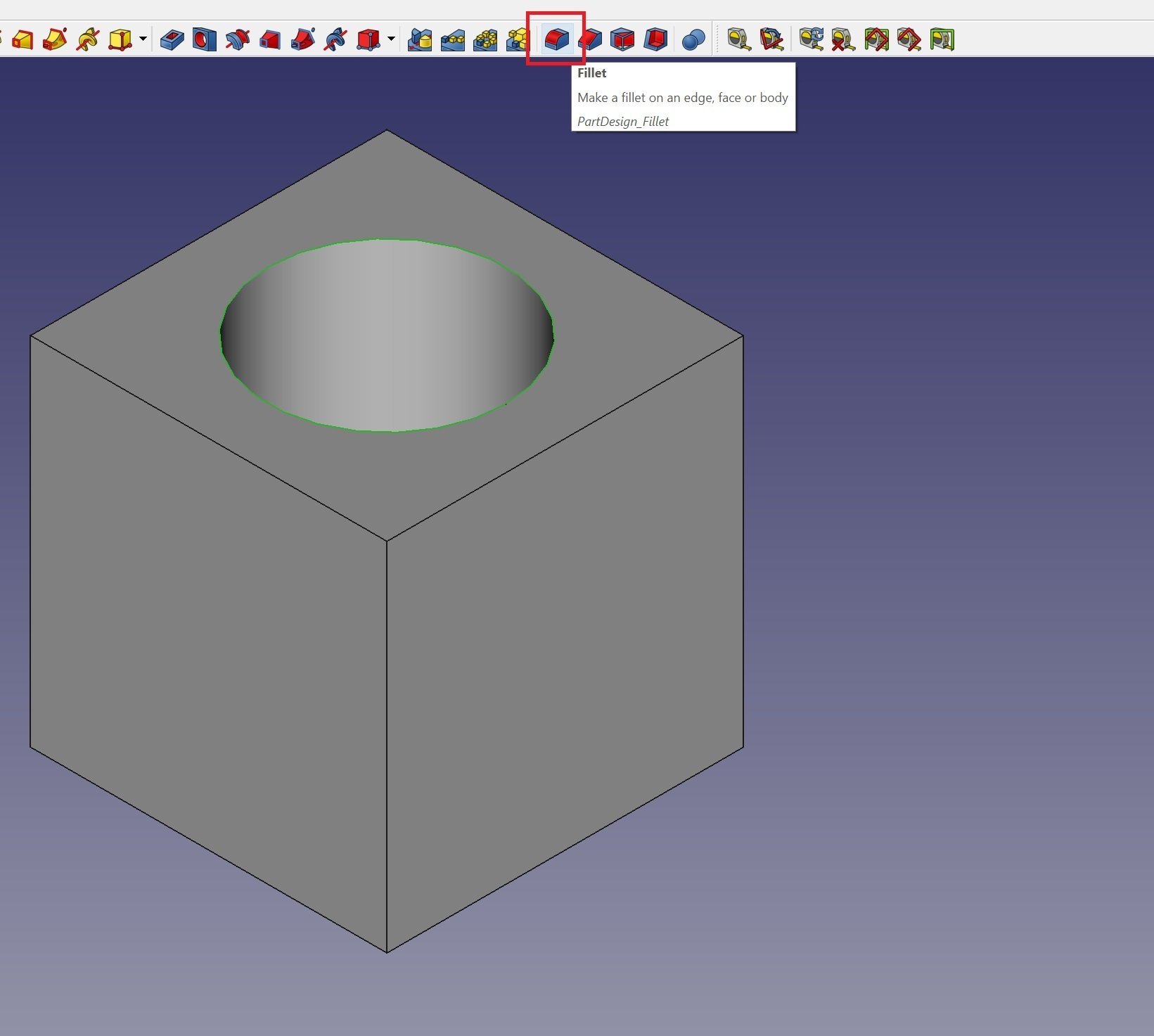

I got stuck on googling how to make a fillet in freecad, to which the answer appeared to be, “yeah, nah, you sort of can’t”. Oh okay, this program is not for me.Edit: if people want to help/criticise, I recall the problem was that I couldn’t do it parametrically, which is the only way I like to model any engineering parts. So far the only thing that information has gotten me is a downvote. If freecad is as full featured as you say, then this should be easy to do. Feel free to tell me how.EDIT 2: after the info I got, I looked into it more and discovered my problem was a bit different - I couldn’t do a parametric offset line in a sketch, because I needed to make a particular pattern. I ended up doing it with OpenSCAD if I recall. I apologise for saying freecad couldn’t do fillets, that would’ve been extremely basic. It was still a very painful experience just to figure out that it couldn’t do what I needed.

whens the last time you used freecad? theres literally a button for making fillets.

For years, in fact.

I tried using Freecad as to filet something recently and it told me to look at the error console for more information, after googling for where the error console is, I realized the message to look at the error console was being output to the error console.

There was no more information to be had. It is a UX and functional nightmare, and it is what it is, but the downside is this means millions of engineers are being trained on subscription web sites, and eventually this will be used to both squeeze people for money, and also to prevent people from creating unauthorized or patented parts.

I honestly forget, it was such a terrible experience I didn’t give it any more time. I think that the problem was that I couldn’t make it parametric.

the fillet button 🤯

Exactly the words that I had come to mind lol

Huh, I’ve definitely done fillets before. Though they’re more nuanced than F3D or SW or ProE.

I’ve found freecad to be feature complete and fairly performant as a pure CAD tool, but the workflows take getting used to and there are some rough edges where things are just significantly more complex than in competing commercial software.

I think SolveSpace and OpenSCAD have trouble with fillets, but FreeCAD should be fine, though as a person with a non-technical background, FreeCAD is still generally miserable to use.

I don’t know how long ago you tired this (early versions were, even I will admit, kind of crap) but in the current FreeCAD release of 0.22.1 it’s incredibly easy.

Just select the edge(s) you want to fillet and and press the “fillet” button in the Part Design workbench…

And on the panel on the left you can set the radius. The profile of the Fillet tool is always a 90 arc of circle with the radius you’ve specified.

Or, if you want to get fancy and make your own bespoke custom fillet. Well, you can define its profile in a sketch. Here I just used a bezier to make an arbitrary curved shape. You are defining the profile of the material you want removed here, i.e. the negative space. You can make this as mathematically rigorous and precise as you like.

Then, position it somewhere on the vertex you want to profile and once again in the Part Design workbench, select that sketch, and hit “subtractive pipe.”

From there, you can hit “add edge” to define which edge(s) you want it applied to. You get a preview of the material removed.

Et voila.

I appreciate all the effort you went to, and I can do this as it turns out. Now that I’ve researched what problem I was having, it turns out the issue was that I couldn’t do a parametric offset line in a sketch, which was crucial to what I was doing at the time, so I had to give up on it.

I was using 0.19 at the time, because that’s what I’ve got installed.

I’m curious what a parametric offset would be. If it is what I think it is, I’ve accomplished that with some construction geometry. Add a construction geometry line constrained appropriately (e.g. perpendicular to some other line, particular length, etc) and then use its other end to attach and constrain the offset line.

Yeah, that’s what it is. That would probably work at least for straight lines, which was the case I was doing.

I would love for you to explain how the workflow is any different than in something like SolidWorks? I use SolidWorks in my day job and I use FreeCAD exclusively for my personal projects. It was a pretty seamless transition for me. Sketch->Feature, repeat, paying attention to order of operations in your model tree. What’s so different?

Is FreeCAD’s UI a little rough in places? Perhaps, but a lot of the things that people complain about in FreeCAD are present in commercial software. If there’s one thing that SolidWorks might do better is allowing you to get away with things like over-defining geometry accidentally. It’s more forgiving of lazy modeling.

FreeCAD has improved significantly in just the last few years. There is a good community around it. We need more people using it and learning how to model.

Very true, and the reason I went with Fusion in the first place. It’s easy to pick up while still being fully featured.

How about OnShape

OnShape is free but explicitly non-commercial if you don’t pay, and it requires your models to be publicly available in a potentially weird way where someone else could make money from your stuff but you can’t. It’s a weird AF licensing setup.

I like their pricing scheme though, because most makers work on open source.

Open source is not the same as, “you are barred from commercial use,” which is why I hesitate with OnShape. At minimum, these companies need to tighten up their licensing terms to be strict but fair.

to wit, Creators have this:

Trial or Free Versions. Trial and free versions of the Service are made available by Onshape. Trial versions of the Service are intended for evaluation purposes, and may be used for commercial or non-commercial purposes during the evaluation period. Free versions of the Service are intended to support (a) creating and editing intellectual property for non-commercial purposes, and (b) viewing, commenting and import/export for commercial or non-commercial purposes (to the extent the plan offers those features). If you intend to use the Service outside a trial context to create and/or edit intellectual property for commercial purposes (including but not limited to developing designs that are intended to be commercialized and/or used in support of a commercial business), then you agree to upgrade to a paid subscription to the Service. Trial and free versions of the Service are otherwise subject to the terms of this Agreement.

but consumers have this:

For any Public Document owned by a Free Plan User created on or after August 7, 2018, or any Public Document created prior to that date without a LICENSE tab, Customer grants a worldwide, royaltyfree and non-exclusive license to any End User or third party accessing the Public Document to use the intellectual property contained in Customer’s Public Document without restriction, including without limitation the rights to use, copy, modify, merge, publish, distribute, sublicense, and/or sell copies of the Document, and to permit persons to whom the Document is made available to do the same.

Maybe there’s some nuance I’m missing, but on its face that’s total bullshit. You can use the trial version for commercial purposes as long as you don’t intend to KEEP doing so, but not the free version. Meanwhile, you are automagically granting a license to commercialize your files for literally everybody else. Sloppy at best, exploitative at worst.

OnShape

I’m sticking to FreeCAD.

I spent a lot of time in free cad and am now trying Bricscad. I wanted to use Alibre because it’s way cheaper but it’s windows only and I couldn’t get it running in Proton or Wine.

I like freecad a whole lot, but I couldn’t stand the number of crashes any longer :(

I couldn’t find any other sane priced software that wasn’t Cloud-integrated (looking at you, dassault).

Huh, I never had crashes.

Even with an Edu License for Autodesk, I HATE the UI.

Not sure why it happens.

Just using it on fedora as installed from the repos.

Try the latest appimage. I use thoses.

Me too. While it’s probably not as good as commercial packages, I’ve yet to encounter something I can’t model. Once the topological naming problem is gone (should happen soon) it’s gonna be a delight to use.

The TNP is problably one of the most infiriating bugs FreeCAD has.

Once that’s gone, i’m sticking to FreeCAD till I get bored with this hobby or I die.

I didn’t know it had an acronym now ^^

Opps, it doesn’t…

deleted by creator

It’s such a bad piece of software I just don’t get how people can use it…

There was a bit of a learning curve but after a few days I found it works very well for my needs.

Idk, I tried it several times, it’s just bad.

How?

Just in case anybody doesn’t know, if you’re a US or Canada veteran, solidworks is $20 a year

Will need to look into this thanks!

So if you make 1000$ in a year from modeling, 680 goes to fusion360

Revenue does not mean profit. So if you sell something that costs $800 in material, soll it for $1000, you still need to pay for fusion…

And then If that’s all you sold that year You’re all of a sudden at a $480 loss.

It’s just like rent inflation while wages stay the same

Cost of business is factored into price to the consumer. A single freelance contractor trying to help pay rent and groceries for his wife and 2 kids shouldn’t need to eat the increase at the expense of his family’s financial support, so he charges more for his services.

A big company will also increase their costs likewise, but they already have expenses covered and the extra money goes into stock buybacks and board member compensation packages.

And if you make $70,000 in a year from it, $680 goes to Fusion360.

Let’s stay realistic here, mmkay?

Just use the same creative^W standard accounting practices that all other companies use. Take Google for example… we all know that they don’t pay any taxes, because they don’t earn any positive revenue. Right?

So I’d like to use the same approach. I would not be the one making $1000. That would be my, um, cousin, who just happens to live in Bermuda. HE is the one making all that money, not me! So I don’t have to pay the $680, right?

(By the way, can I also stop paying taxes and be worth a trillion dollars now? No? Why not?!?!)

If you want a net profit of $1000 you would need three subscriptions

I am on my 7th or 8th year of it. I don’t use it for making money, but use it for making 3D printed things for around the house, then upload them to Thinginverse and Printables for everyone else to use.

It looks like Solidworks for Makers is US $48 / year.

A couple of answers from the Q&A at the bottom of the page:

“3DEXPERIENCE SOLIDWORKS for Makers is meant for personal projects and non-commercial use. Per our terms and conditions, you may sell items you make for a profit up to and not exceeding US$2,000 a year. If you are interested in building your business with SOLIDWORKS tools, check out our start up program or our commercial offers.”

“Currently this offer is available for purchase with a billing address within the following countries: Algeria, Australia, Austria, Belgium, Canada, Czech Republic, Denmark, Finland, France, Germany, Ireland, Italy, Japan, Luxembourg, Morocco, the Netherlands, Norway, Poland, Portugal, Spain, Sweden, Switzerland, the United Kingdom, and the United States. More countries will be added soon.”

“Files and data created with your Maker account are digitally watermarked and can only be opened up in another Maker platform. You cannot open up files created with your Maker account within a commercial or academic platform. This digital watermark is added to native 3D file formats, such as .3dxml, .sldprt, .sldasm, and .slddrw. Neutral 3D file formats, such as .stp or .iges can be opened on any platform.”

Oh wow, thanks for this! I’m a veteran and $20 a year is awesome! I do the same, mostly just making things around the house. I don’t really upload them though, because most things I make are super custom to my needs.

If that’s the case, you don’t need to be paying for Fusion. You should qualify for the free, personal license.

Yeah, I make things for me and family, but you’d be surprised at how many other people would be interested in it as well. I certainly was. I looked at my Thingiverse analytics, and I’ve had 10’s of thousands of downloads of my things. I know those don’t directly translate into prints, but I was shocked at how many people downloaded my designs that were originally just for me to organize my sandpaper, or sift sand or hold my CNC collets and wrenches. . .

Are you familiar with the watermark they are talking about? How does that express itself; does it show up on models or is it like metadata in a file?

I don’t know exactly how it is implemented, but if I had to guess, it is probably just metadata in the file. I know that when I print out the 2D drawings I make, it puts text in the bottom corner with something to the effect of “This was made with the educational version of Solidworks, Not for commercial use” or something like that. I expect something similar if you tried to open a file made on the educational version on the commercial version, there would be something similar on the screen. Not sure though, since I only have the educational version.

It’s a very sticky watermark. If you open and save a file in educational, the watermark cannot be removed even if you open it in paid commercial version later.

I’ve not heard anything good about 3DEXPERIENCE, I really wanted to get it but after reading what other people have said, I decided not to.

I tried it and made a few things for around the house.

It’s fine, but it’s Invasive, and so cloud connected that I got really fed up with it.

I would pay them the same price for an offline only version.

Thanks for the tip, I use SW at work. This would work out well for me.

I use CATIA at work, and it’s funny how both programs are made by Dassault, but have such different interfaces.

Probably bought by Dassaut and developed by different teams

I’ve searched for this and couldn’t find it. They must hide it well. How well does it run on Linux?

Sorry, I don’t have the slightest idea.

Probably not well. Its drm does some weird shit where it (3dexperience) runs in the background and then launches a web page that has you log in and you launch and update from the browser. I think there’s a way to directly launch it with a shortcut but all in all it just does so much weird shit that i haven’t even tried.

I miss Autodesk Inventor but i can’t remotely justify the price for dicking around with personal projects and solidworks for makers is a pretty damn good deal. Plus SW seems like the industry standard so looks better on a resume? I’m a programmer so it doesn’t really matter but meh.

OnShape might be okay, probably runs just fine on Linux, but i hate that its cloud based. I just want to own my software goddamnit.

One day we’ll have a foss parametric non-destructive blender-level cad suite. FreeCAD and OpenSCAD are neat but not really what I’m looking for.

I’m ranting again…

Can’t say you own any 3d cad software anymore anyway since they all went to subscription only about 10 years ago.

It’s one of the biggest problems of the whole 3d printing ecosystem that so many people are relying on software like fusion or tinkercad that could shut down, lose its free option, and see massive price increases on subscription software.

I wish I could wrap my head around freecad, but we’re just not there yet and we may never be. I feel like it or something like it must be our future because until we have a full libre software chain we’re living on borrowed time.

I’ve started watching a freeCAD tutorial series on YouTube. It’s a little slow going, since I don’t have a huge amount of time to dedicate to it, but it’s amazing how quickly the basics can be picked up.

There is going to be a TON of progress next year. I think 2024, freecad will be very usable for hobbyits.

2024, the year of

Linux desktopFreecadAlways 1 year away!

I’m a hobbyist, and I find FreeCAD very usable already. But then, my beard is long enough that I remember all of the art and design I did back in the day in all those old janky software packages running in DOS (sometimes even in as much as 640x480!) so maybe my tolerance for obtuse horseshit is higher than most.

Hey, give us one of those cool privacy respecting links if you don’t mind :)

thanks!

I wish I could wrap my head around freecad, but we’re just not there yet and we may never be.

May I ask why it is that you say this?

I also have this question. What is so different about the workflow between FreeCAD and other 3D CAD software? If you can do one, you can do the others.

FreeCAD is a strange mix of over-designed and unfinished.

There’s like three different workflows for doing parametric CAD, plus a drafting workflow for an AutoCAD architectural experience, plus workbenches for meshes, NURBS, etc. Occasionally a tool you need will be in another workbench. There is no official assembly workbench included. It’s not exactly obvious how workbenches work together. A lot of shortcuts which have become Just How You Do Things in other CAD software aren’t present, so you have to do things an awkward long way. Add-ons and macros can help…but are poorly documented if at all.

The learning curve is steeper mostly due to tools not having as intuitive names and ui layout.

I dove into fusion 360 last year and was making functional and nice parts within the first couple of hours. Since moving to Linux I’ve tried freecad and while I can eventually find the tools that do the same things, it is less intuitive to get there.

Additionally, when I run into a roadblock in fusion 360, I can usually find quick and easy explanations or tutorials for it, and just have not had the same luck with freecad. I can usually get the hurdle crossed with the tutorials but I find I have to look up the same stuff often as it doesn’t stick.

This is all nebulous as all hell, I admit. And I can vaguely tell that it does all the same things similarly to fusion 360, but it’s just different and obscured enough that I feel useless and obtuse using it and spend more time searching for tutorials and answers than I do designing.

I want to learn it. I want to use it. But I still find myself in fusion 360 when I need to get a part designed sooner rather than later - it took less effort and faffing around to get fusion 360 working in proton ge than getting to a stable point using freecad.

Well put. I have the exact same experience.

I’ve got an IQ of 87. So far, tinkercad is basically the best 3d modelling program for me so I can make stuff by using arrow keys to move around basic shapes.

XD

Well at least you’re honest

Rhino 8 is very easy to use now with a new option like in sketchup for push/pull. They have a perpetual license so no subscriptions.

I’ve just become a CAD hobo or squater you could say. There will always be one ““free”” piece of cad software that caters to the casual 3D printer and I’ve just accepted that they will inevitably raise the price and I’ll just have to jump ship again. But, at least I get to keep all the knowledge and that is what counts.

Uhm, what about Blender?

Blender is not designed as a CAD software. It is for 3d modeling. So you would use Blender to make graphics for a video game, or a 3d movie.

CAD is more for designing things to be made outside of a computer, so 3d printing, CNC or stuff like that.

Blender doesn’t consider the object as a whole, and can leave holes that a CAD setup would handle.

You can still use blender though if you know how to model in it already. Just don’t leave holes and you will be fine. I use that for a lot of 3d prints I make just because I am already comfortable with it.

Blender workflow is very different to a CAD workflow. It’s ok for small things, but if you need to design some complex functional parts with tight tolerances, you will waste a lot of time in Blender.

blender can be used as cad software, but for any practical application, you want parametric design.

I used to use a lot of Autodesk software as a hobby by abusing their student versions but they’ve really tightened their belt on those lately. I always thought if I turned a dollar on one of those old projects I’d absolutely want to give Autodesk their fair share but if they’re going to be greedy then fuck em.

I’ve been using Solid Edge for a while -it’s very solid once you learn it, just a less mature UX compared to 360. But no bullshit, it just works, I love not losing work because half the system is in the cloud and randomly forced you up to log in.

I love synchronous mode for quickly adjusting parts. Otherwise the standard mode works pretty much the same as solid works with some quirks.

Lol that’s worse than Adobe pricing

Autodesk have always competed well with Adobe at screwing over their customers.

And they make it tricky as hell to find the hobbyist license. I really hate this exploitative shit. Same for Adobe.

Fusion is still the cheapest CAD software out there

Is it thou?

I was looking at Solidworks and it looks like I can sub for $99/year

https://www.solidworks.com/solution/3dexperience-solidworks-makers

Says 48$/year or 15$/month for me.

Yeah, sorry… I think it’s $99CAD but yeah, $48US

No need to apologize, even if it supposedly is the custom in your part of the world. 😉 You still pointed out something that I didn’t know about and for that you have my eternal gratitude. Not much of it, mind, but some of it.

I’ve been considering switching to this but I’ve heard a lot of bad things

Come, join us: FreeChads

Makes me glad I still have access to my old university email and credentials.

I switched to Shapr3d a few years ago, but I follow the work of the FreeCAD team with great interest.

IMHO, I think Autodesk should provide a free/limited version of Fusion360 for the people who only want to design and 3D print small pieces

They do. It’s free for personal/non-commercial use.

As a hobbiest who’s relatively new to CAD, I wish I liked Shapr3D more than I do. I want to use it on my Mac but everything is multiple clicks away compared to other software and it seemingly has fewer keyboard shortcuts to compensate :/

Also, this is probably user error but I could not for the life of me figure out how to make the spout on teapot for a Halloween costume in Shapr3d. Spent maybe an hour and a half on it. Ended up installing Fusion360 and had it done in about 30 minutes. I don’t know the term for it but getting an extrusion to follow/form to a bunch of different sized circles in Shapr3d wasn’t doing what I expected.